The Missing Intelligence Layer for the Physical World

Why AI can’t build what it doesn’t understand and how a new system of intelligence will bridge data and design.

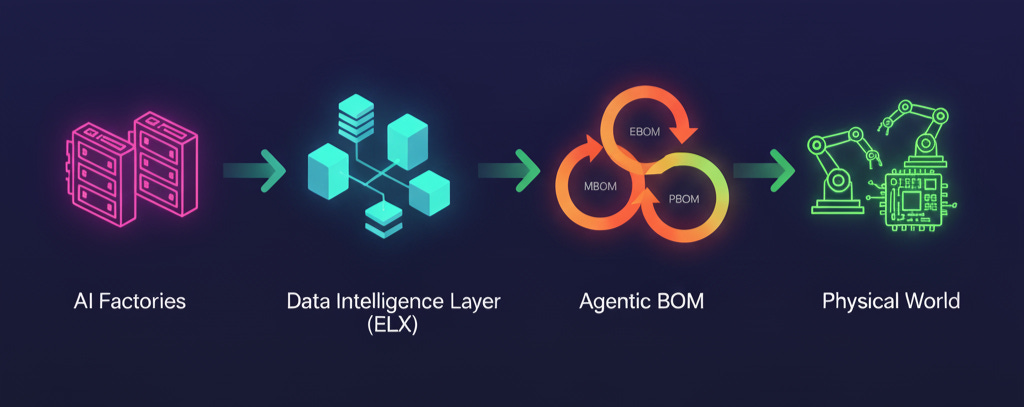

The Rise of AI Factories

The world is entering the era of AI factories - large-scale systems that transform data into intelligence, much like traditional factories turned raw materials into products. They represent a new industrial paradigm: data as the raw material, GPUs as the machinery, and intelligence as the output.

For all their power, today’s AI factories share one critical limitation. They can create digital intelligence, but they cannot yet build the physical world - the systems, components, and materials that make ideas real. They can generate and optimize, but they can’t reason through the engineering trade-offs that make something manufacturable.

They know how to imagine; they don’t yet know how to build.

That blind spot motivates a growing body of work across the ecosystem, including the approach described here.

The Data Intelligence Layer for the Physical World

Every physical product is bounded - and enabled - by its components: semiconductors, sensors, interfaces, connectors, enclosures, adhesives, alloys. The truth about those parts, their limits, capabilities, compatibility, lifecycle, compliance - lives inside millions of dense complex datasheets and supplier documents that contemporary AI cannot reliably reason through.

This has led to interest in an AI-ready Data Intelligence Layer for Components: a verified, engineer-grade knowledge graph of component behavior, constraints, and equivalences; continuous transformation of multimodal data (text, pinouts, curves, graphs) into structured, explainable intelligence; and interfaces that let AI systems reason at design time and shift critical decisions left into simulation, optimization, and sourcing - before production begins.

One implementation of this concept is Wizerr’s ELX Engine - positioned as a complete system of intelligence rather than a simple ingestion pipeline. ELX is designed to interpret datasheets in an engineer-like manner and reconcile fragmented supplier realities into consistent, computable truth.

From Data Intelligence → Agentic BOMs

With a domain-verified data intelligence layer in place, the Bill of Materials evolves from static lists into a connected reasoning graph - linking EBOM (engineering), MBOM (manufacturing), and PBOM (production and procurement) into one continuous, intelligent workflow.

Built on this foundation, Wizerr’s Agentic BOM embeds component-level intelligence directly into every part decision, enabling teams and AI systems to:

Select and qualify parts with verified specifications and constraints,

Propose alternates that remain fit/form/function-correct and lifecycle-safe,

Align compliance and supply in real time, and

Explain trade-offs with transparent citations to underlying data.

The result is a new kind of design-to-manufacture workflow - faster, safer, and grounded in a shared intelligence substrate that unites engineering, sourcing, and production.

Why This Layer Matters

Across industries, the bottlenecks are consistent: engineers spend hours interpreting datasheets instead of designing; procurement chases fragmented truths; supply chains react rather than predict. As AI factories scale, a component-level intelligence layer becomes non-optional infrastructure. Without it, AI remains powerful but confined to digital reasoning - disconnected from the realities of making physical things.

Solutions like Wizerr’s ELX data intelligence layer and Agentic BOM aim to provide the bridge: verified, structured intelligence that closes the loop between design, sourcing, and manufacturing.

From Generative to Agentic Intelligence

The past few years produced generative AI - systems that create, simulate, and predict. The next chapter is agentic intelligence - systems that reason, decide, and collaborate alongside humans to design and build the physical world.

This is not about AI replacing engineers; it is about engineering itself becoming intelligent, powered by verified, contextual data and reasoning systems that connect design to manufacturing.

In that context, platforms such as Wizerr position their data intelligence and Agentic BOM layers as enablers that help AI factories move from imagination to creation.

Looking Ahead

The convergence of AI factories, component intelligence, and agentic workflows points to a profound shift: design, sourcing, and manufacturing operating as a single, intelligent system.

The AI that writes, sees, and predicts has already arrived.

The AI that builds is next.

And it starts by understanding and operationalizing the smallest parts that make the world work.

OpenELX is a forum for the Physical × AI ecosystem — connecting engineers, researchers, and builders shaping the next generation of intelligent manufacturing and design. To contribute or respond to this piece, contact openelx@gmail.com